-

-

AT468 – Multi-station Handler for Leadless Packages AT468 is a high speed multi-function scan-pack handler engineered for Lead and Leadless packages. This fully automated design consists of a primary 24- station rotary turret coupled with a secondary multi-station inspection table. The modular concept allows for media transfer flexibility, supporting a wide range of I/O configurations. These include plastic tube, multi-channel metal magazine, vibratory bowl, Jedec tray and reel. Single or multiple test stations can also be integrated into the AT468. STI’s proprietary vision technologies are employed to provide ONE Vision Solution for all package types. This architecture provides our customers with a powerful one-stop strategy, facilitating standardisation of quality assurance inspection techniques.

AT468 – Multi-station Handler for Leadless Packages AT468 is a high speed multi-function scan-pack handler engineered for Lead and Leadless packages. This fully automated design consists of a primary 24- station rotary turret coupled with a secondary multi-station inspection table. The modular concept allows for media transfer flexibility, supporting a wide range of I/O configurations. These include plastic tube, multi-channel metal magazine, vibratory bowl, Jedec tray and reel. Single or multiple test stations can also be integrated into the AT468. STI’s proprietary vision technologies are employed to provide ONE Vision Solution for all package types. This architecture provides our customers with a powerful one-stop strategy, facilitating standardisation of quality assurance inspection techniques. -

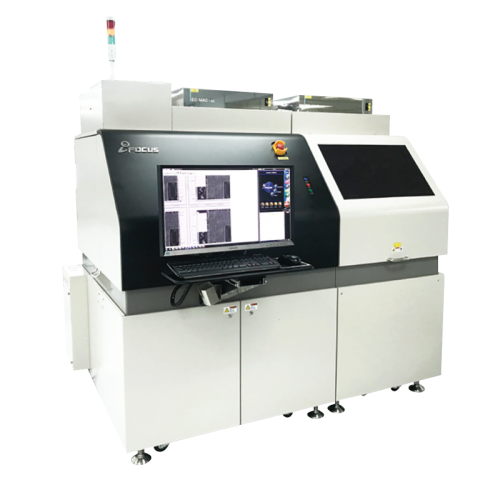

iFocus

STI’s iFocus is a highly intelligent precision wafer inspection system that offers a comprehensive solution for the inspection of frame and/or whole wafer. Using STI’s proprietary On-The-Fly (OTF™) vision, the iFocus can be configured to detect any type of micro defects arising from wafer processing, post dicing or packing. The OTF™ optical system encompasses pioneering technology in areas such as optics and illumination design, 2D, 3D and active die inspection algorithms. Patented Simultaneous Dual Illumination Image Capture Technology is used to eliminate escape and reduce overkill without compromising throughput. -

Hexa Evo / Evo+

2D/3D High Speed Scanner for Large Form Factor Packages The Hexa is the latest addition to the highly successful Integra Hexa family. It provides the most comprehensive quality assurance solution for detection of backend process induced defects for all ball array, peripheral leaded/leadless and large form factor packages. The highly modular design concept allows flexibility for various options like – Dual taper, auxiliary tray input, top and bottom surface inspection, side surface inspection etc. Simple and repeatable conversions also make the Hexa Evo perfectly suited for customers with high mix, small lot size production environment. STI’s proprietary vision solution encompasses pioneering technology in areas such as optics design, lighting control, and software algorithm. Coupled with advanced automation features, the Hexa Evo offers a diverse menu of inspection and output options configurable to match all package requirements.- Top Package Visual Inspect (PVI) with orientation checking and correction

- Bottom PVI

- 3D On-The-Fly Lead / Ball Inspection

- Symbol Inspection

- In-pocket Inspection

- Dual Tape & Reel

-

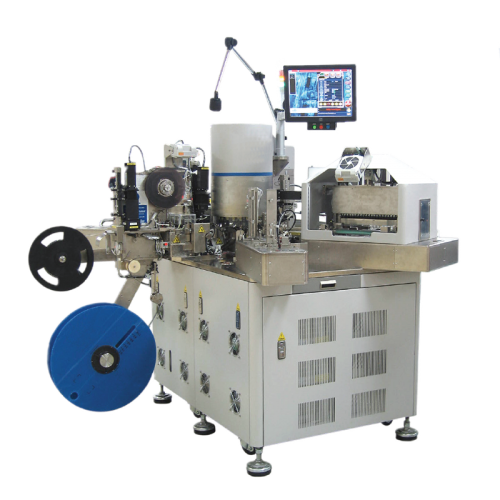

TR48MK5 - Tape & Reel System with 2D Inspection

The TR48MK5, a high speed Tray Taping System with unique triple head pick and place design, combines high performance with ease of operation. The system designed provides a 2D in-pocket vision inspection solution for lead and mark with an autosort reject management capability.